Setting the Standard for Load and Haul Efficiency

DISPATCH Fleet Management System

DISPATCH provides your mine with end-to-end monitoring of production and auxiliary equipment, helping optimize your operations to achieve planning objectives, increase equipment utilization and more.

Join teams around the globe who use DISPATCH to help:

- Reduce total cost per tonne

- Increase efficiency of their current fleet

- Improve execution of their plans in every shift

- Reduce hang and queue time

Maintain and update a real-time digital twin of your mine equipment, locations and haulage roads with DISPATCH. This fleet management system continuously optimizes your routes and utilizes automated communication to help keep your truck operators informed and connected.

ProVision Guided Spotting System

Help your operators get to the right load spot – the first time

Built on nearly 20 years of machine guidance success, the newly-released ProVision Guided Spotting system utilizes advanced guidance technology and high-precision GNSS positioning to provide centimeter-level accuracy for your truck and shovel operators.

Optimize your load cycle with precise guidance and intuitive visuals, helping your haul truck operators hit the spot the first time they reverse toward the shovel – without the need for a hanging bucket or flag.

Argus Payload Monitoring System

An advanced monitoring system to manage shovel and truck payload

Argus improves digger operator technique and performance with real-time feedback, peer benchmarking and in-seat coaching. The world-leading payload management system weighs each bucket in real-time without the need to stop and calculate payload before dumping into the truck.

Developed on an open API platform, the interoperable system works on any OEM machine and is available on electric rope shovels, hydraulic excavators and wheel loaders. Get more out of each and every bucket load by helping to optimize your truck loading and payload management.

Pegasys Dragline Monitoring System

Pegasys is the world’s leading payload and mine compliance monitoring system for draglines.

Pegasys delivers improvements in operational efficiency, safety, and productivity through precise, reliable payload information, visual guidance intelligence and live operator feedback.

Boom-mounted laser scanners and GPS sensors continuously scan and map the terrain around the dragline, while strain gauges are mounted in critical locations to provide stress and structural monitoring information.

Experience how mine sites worldwide have leveraged DISPATCH to:

Increase total material moved by >10% Per Year

by “unlocking” equipment assignments

Save nearly $1 Million per year in fuel costs

by reducing unnecessary idle time

Reduce truck queue times by 28.6%

by dynamically reassigning equipment

Increase production by 6.6% loads per shift

by automating shift change process

The ProVision Guided Spotting system has the potential to:

Contribute up to 2-8 additional loads per hour

by maximizing truck and shovel efficiency

Increase productivity by up to 13%

by eliminating bucket spotting

Reduce shovel hang time by up to 35%

by precisely guiding haul truck operators to the right spot

The Argus Payload Management system has the potential to:

Improve operator performance by up to 21%

Through real-time, in-seat coaching and payload information

Increase production by up to 6.5%

by better utilizing current fleet

Move up to an additional 1M tons

by consistently hitting shovel payload targets

The Pegasys Dragline Monitoring system has the potential to:

Improve dig rate by up to 17%

Reduce swing time by up to 12%

Reduce machine stress by up to 9%

Elevate your fleet management and operator efficiency to increase the performance of your loading and hauling operations through:

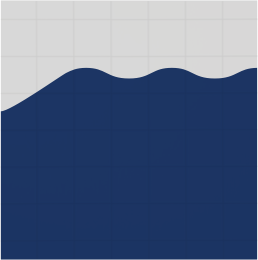

Without Optimization

DISPATCH FMS:

- Purpose-built fleet optimization

- End-to-end monitoring of production and auxiliary equipment

- Compliance with planning objectives

- Minimized hang and queue times

With Optimization

ProVision Guided Spotting System:

- Minimized shovel hang time

- Minimized truck re-spotting

- Maximized trucking capacity

- Optimized shovel swing angle

DISPATCH System – Key Features & Benefits

ProVision Guided Spotting System – Key Features & Benefits

Argus Payload Management System – Key Features & Benefits

Pegasys Dragline Monitoring System – Key Features & Benefits

Did You Know?

The DISPATCH FMS is the supervisory technology for Komatsu’s Autonomous Haulage System

Get even more value from your Mine Management Systems

Performance Assurance

Consulting Solutions | Customized Consulting

A dedicated team of Modular specialists collaborates with your mine personnel to establish mutually-defined goals and milestones, delivering even more value from your MineCare system.

- Enhance equipment productivity

- Reduce truck queue times

- Improve net production through shorter shift change duration

- Reduce equipment maintenance costs

"In the Performance Assurance area, they send a wide variety of professionals to the site to help deal with the different problems we have. We got some solutions to some of the problems we had and it was a great win for us. "

- IntelliMine Client in North America

MinePlan Compliance

Consulting Solutions | Customized Consulting

Our technology-based consulting approach helps you create synergy between departments, processes, and systems, thus increasing your ability to consistently execute according to plan.

- Facilitate the cultural shift your personnel may need to accept and internalize changes to operating procedures and best practices

- Improve efficiency, performance, and process control

"They really helped us find the opportunities to increase the overall performance of the mine - certainly provides added value. It added value to our operation."

- Mine Plan Compliance Client in North America

Featured Resources

Sustain Your Value: The Big Picture

Leverage Modular Mining’s full solutions suite to truly maximize your value, sustain your improvements, and grow over time. Each system and service builds upon another, providing more value and process improvements than you can derive from just a singular technology.

Without Modular Mining Solutions

With Deployment Services

With Customer Care Package

With Value-add Services